Supply chains were heavily affected by the COVID-19 pandemic, and the electronics industry was no exception. Shutdowns slowed production at the same time consumer demand was changing and, in certain sectors, increasing. After months of challenges, the industry is still dealing with electronic component shortages all over the world, and those shortages are impacting businesses of all types and sizes.

What Industries Are Impacted by the Electronic Component Shortage?

Because semiconductors are used in a range of industries, the available electronic component supply has a far-reaching impact. In particular, these three industries are feeling the effects of the shortage:

- Automotive: Despite the temporary downturn in demand for cars, the automotive industry is undergoing massive changes that makes manufacturers more dependent on the electronic component supply. With more sophisticated sensors and automated systems, more complex electronic parts are required that meet the standards for safety and warranties. As the demand for electric vehicles continues to grow, the need for electronic parts will grow with it.

- Smartphone/Tech: The demand for smartphones dropped severely during the pandemic, but it’s expected to recover. As it stands, the industry uses about half of the multilayer ceramic capacitors that are produced every year.

- Power/Energy: The electronics component shortages impact LED lighting, which hinders construction—an industry that is facing challenges with other supplies, as well. It could also slow the renewable energy movement.

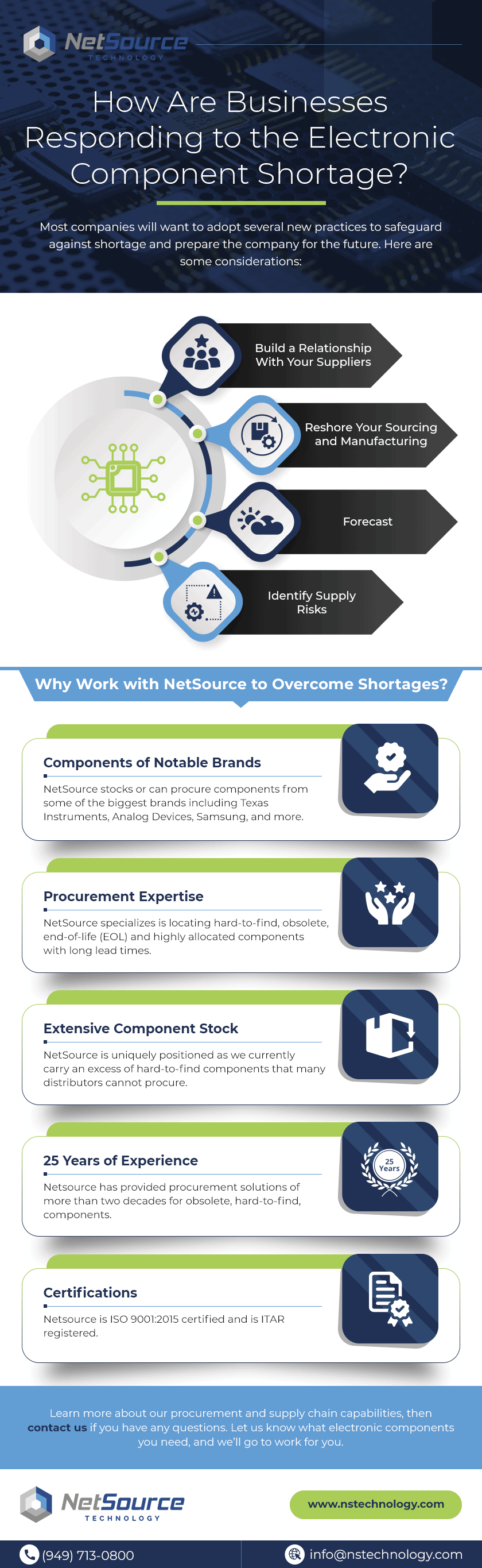

How Are Businesses Responding to the Electronic Component Shortage?

Surviving and thriving as a business throughout these shortages requires a strategic approach and careful planning. Most companies will want to adopt several new practices to safeguard against shortage and prepare the company for the future. While a crisis and its lingering effects may inspire these types of changes, most of them are good habits that will continue to serve your company as we all move forward. These strategies may include:

- Build a Relationship With Your Suppliers: Get to know who you’re working with, and maintain an open line of communication as deep into your supply chain as possible. Your suppliers are your teammates, and that close relationship will help you stay in the loop and find solutions.

- Reshore Your Sourcing and Manufacturing: Keep your supply chain smaller and closer to home shortens lead times and makes it easier to communicate about changes and challenges. At the same time, you may want to identify and connect with suppliers around the globe; if your domestic source can’t deliver, you may have an alternative you can turn to.

- Forecast: Share your product forecasts with your suppliers, so they can plan ahead with you. As you change the forecast, keep them updated. Avoid buying and stockpiling based on fear: continue to take a strategic approach to your needs and purchases.

- Identify Supply Risks: With some lead times extending for months, it may be useful to order a stock of components before you need them. You need to weigh the pros and cons of spending that money upfront, counting on consistent demand for your products, and the danger of running out of that part and not being able to get it for weeks or months.

Since 1997, NetSource Technology, Inc. has specialized in locating obsolete, hard-to-find, end-of-life, and highly allocated electronic components with long lead times. With an extensive network of trusted suppliers and years of supply chain experience, we are one of the largest independent stocking distributors of electronic components and global procurement services. We maintain a stock of millions of electronic components for your convenience.

Headquartered in San Clemente, CA, with offices worldwide, we support you through the entire supply chain cycle, offering exceptional quality control as demonstrated by our ISO 9001:2015 certification and ITAR registration. Learn more about our procurement and supply chain capabilities, then contact us if you have any questions. Let us know what electronic components you need, and we’ll go to work for you.