Enhancing Business Procurement: Strategies and Services for Success

Procurement is the backbone of organizational operations, providing the resources required for business processes. A well-organized procurement process makes it easier to promptly acquire goods and services, allowing businesses to meet customer requests more efficiently. They can mitigate risks and achieve operational excellence through strategic vendor partnerships and diligent contract management.

(more…)

Navigating Legacy Supply Chain Services: Challenges and Solutions

A legacy supply chain refers to traditional methods and systems used to manage the flow of goods and services from production to consumption. These systems rely on manual processes, paper-based documentation, and limited technological integration. Updating and modernizing these legacy systems can help businesses enhance productivity, reduce costs, and adapt to changing market demands.

(more…)

Thyssenkrupp’s Innovative Approach to Supply Chain Services: A Case Study

Supply chain services are essential for the efficient movement of goods from manufacturers to consumers, encompassing activities from procurement to distribution. Companies in today’s economic environment recognize the need to improve their supply chain procedures to increase competitiveness. Among the pioneers in this domain is Thyssenkrupp, a global conglomerate known for its innovative approach to supply chain management.

Excess Inventory Management for Maximum Yields

Excess inventory or surplus stock is when a business holds more goods than it requires to meet customer demand. When this happens, it often ties up valuable capital that could otherwise be invested in other business areas. In such cases, businesses must prioritize effective inventory management practices to minimize surplus stock and maximize yields.

(more…)

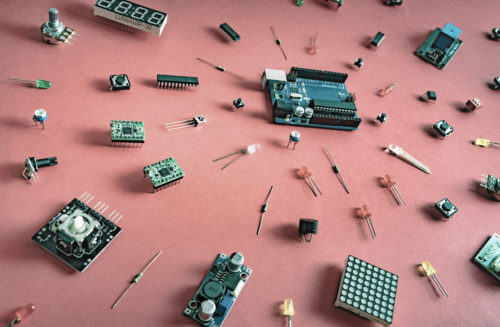

Why Choose a Stocking Distributor for Your Electronic Components

Stocking distributors are companies that purchase and maintain an inventory of electronic components from multiple manufacturers and supply them to customers. They are an intermediary that became popular in the industry, particularly when sourcing parts and components. Moreover, they act as one-stop shops for customers by stocking various products from diverse manufacturers.

(more…)

Understanding Electronics Component Shortages in 2021

Supply chains were heavily affected by the COVID-19 pandemic, and the electronics industry was no exception. Shutdowns slowed production at the same time consumer demand was changing and, in certain sectors, increasing. After months of challenges, the industry is still dealing with electronic component shortages all over the world, and those shortages are impacting businesses of all types and sizes.

(more…)

What Makes Electronic Components Hard to Find?

Sourcing some types of electronic components can prove challenging, resulting in problems ranging from supply chain challenges to halted production. From market demand shifts to supply chain disruptions, many electronic parts have become more difficult to find, including multilayer ceramic capacitors (MLCC) and Microcontrollers. Whatever sourcing challenges you may face, using a procurement solutions provider can make it easier for your business to find rare or difficult components when you need them.

(more…)

Industry Spotlight: Medical Procurement and Supply Chain Management

In the medical industry, developments in patient treatment technologies and techniques have long overshadowed the backend issues industry professionals continue to face. As doctors and nurses adopt new tools to help them diagnose and treat the healthcare facility’s patients, the facility’s procurement team must ensure the inventory continues to satisfy the demand. However, they must tackle and overcome many challenges to fulfill this goal, including out of stock or obsolete items and decreasing budgets.

(more…)

OEM Supply Chain: Inventory Management Tips

As an original equipment manufacturer (OEM), supply chain optimization is always high on your list of priorities. But what does that mean? OEM supply chain optimization is not a quick fix with only one focus, but instead an ongoing strategy. Proper optimization requires analyzing, managing, and ultimately minimizing your inventory and costs, investing in current technology, and developing predictive strategies to streamline production and assembly procedures. Here, the team at Netsource Technology share the top tips for improving your inventory management.

(more…)

Industry Spotlight: Automotive Components Procurement and Supply Chain

In these uncertain times, the automotive industry is facing unprecedented turbulence in every aspect of their business, including equipment shortages, supply chain interruptions, labor disruptions, and a variety of new operational systems and policies. In order to remain relevant in this changing world, automotive manufacturers are rethinking their approach to supply chains and procurement.

(more…)